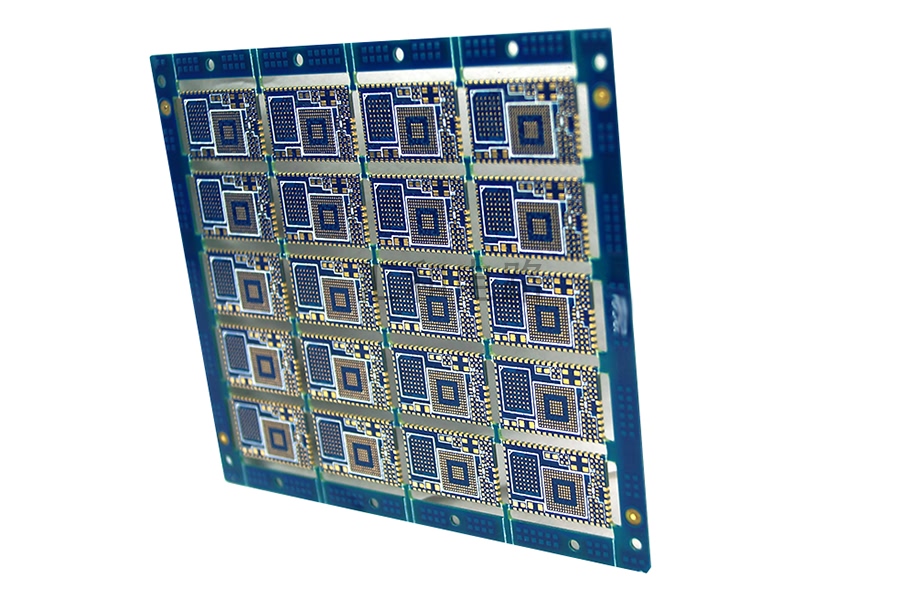

4 lera ENIG PCB 8329

Theknoloji ea tlhahiso ea metallized halofo ea lesoba la PCB

Sekoti sa metallized halofo se khaola halofo kamora hore lesoba le chitja le thehoe. Ho bonolo ho hlaha ts'ebetso ea masalla a terata ea koporo le letlalo le kopaneng ka har'a lesoba la halofo, le amang tšebetso ea halofo ea lesoba mme le lebisa ho fokotseheng ha ts'ebetso ea sehlahisoa le chai. Bakeng sa ho hlola litšitiso tse kaholimo, e tla etsoa ho latela mehato e latelang ea ts'ebetso ea metallized semi-orifice PCB

1. E sebetsana le sekoti sa mofuta oa halofo ea V habeli.

2. K'holeng ea bobeli, lesoba le tataisang le eketsoa moeling oa mokoti, letlalo la koporo le tlosoa esale pele, 'me burr ea fokotseha. Li-grooves li sebelisetsoa ho cheka ho ntlafatsa lebelo la ho oa.

3. Sekoaelo sa koporo holim'a substrate, e le hore mokato oa koporo o koahele leboteng la lesoba le chitja moeling oa poleiti.

4. Potoloho e kantle e entsoe ka filimi ea khatello, ho pepeseha le nts'etsopele ea substrate ka ho latellana, ebe substrate e koahetsoe ka koporo le thini habeli, e le hore lera la koporo leboteng la lesoba la lesoba le chitja moeling oa poleiti e thatafetse 'me lera la koporo le koahetsoe ke lera la thini le nang le phello e khahlanong le kutu;

5. Halofo ea lesoba e etsang poleiti moeling o potileng lesoba le sehiloeng halofo ho etsa halofo ea lesoba;

6. Ho tlosa filimi ho tla tlosa filimi e khahlanong le ho maneha e hatelletsoeng ts'ebetsong ea ho tobetsa filimi;

7. Kenya substrate, 'me u tlose setulo se koahetsoeng sa koporo karolong e ka ntle ea substrate kamora ho tlosa filimi;

Ho eboloa ka masenke substrate e eboloa e le hore thini e tlosoe leboteng le nang le masoba 'me lera la koporo leboteng le nang le litlolo li pepesoe.

8. Kamora ho bopa, sebelisa theipi e khubelu ho khomarela lipoleiti tsa yuniti hammoho, le mohala o fetang oa alkaline ho tlosa li-burrs

Kamora ho maneha koporo ea bobeli le masenke holim'a karoloana, sekoti se chitja moeling oa poleiti se sehoa ka halofo ho etsa mokoti o halofo. Hobane lera la koporo la lebota le koahetsoeng ka lera, 'me lera la koporo la lebota le hokahane ka botlalo le lera la koporo la karolo e kantle ea substrate, mme matla a tlamang a maholo, lera la koporo sekoting lebota le ka qojoa ka nepo ha le itšeha, joalo ka ho hula kapa ts'ebetso ea ho ohla ha koporo;

10. Kamora ho phetheloa ha sekoti se koahelang ebe o tlosa filimi, ebe ho tlosoa, koporo ea bokaholimo ea koporo e ke ke ea etsahala, ka nepo e qoba ho hlaha ha masala a koporo esita le ketsahalo ea potoloho e khuts'oane, ntlafatsa sehlahisoa sa PCB ea sekoti sa metallized

Kopo

Taolo ea indasteri

Lisebelisoa tsa elektroniki

Puisano

Lisebelisoa tsa thepa

Jarolla ka ho iketsa Plating Line

Mohala oa PTH

LDI

Mochini oa Tlatsetso oa CCD

Fektheri ea rona