6 Lera HASL Sefofu se Epeloa Ka PCB

Likarolo Tsa The Patoa Via PCB

Mokhoa oa ho etsa tlhahiso o ke ke oa finyelloa ka ho cheka ka mor'a ho tlamahanngoa.Ho cheka ho tlameha ho etsoa ka mekhahlelo e le 'ngoe ea potoloho.Lera le ka hare le tlameha ho tlamahanngoa ka mokhoa o sa lekanyetsoang pele, ho lateloa ke phekolo ea electroplating, 'me joale bohle ba tlameletsoe qetellong.Ts'ebetso ena hangata e sebelisoa feela ho li-PCB tse phahameng haholo ho eketsa sebaka se fumanehang bakeng sa likarolo tse ling tsa potoloho

The Basic Process Of HDI Blind Patoa Ka PCB

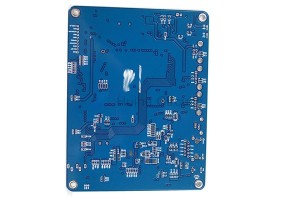

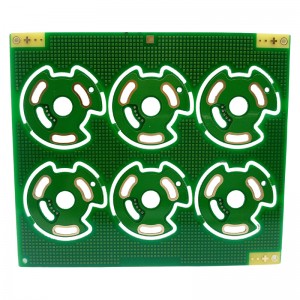

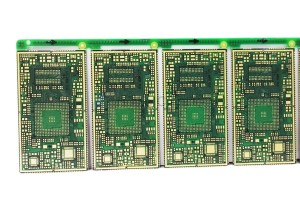

Pontšo ea Lisebelisoa

PCB Automatic Plating Line

PCB PTH line

PCB LDI

Mochini oa Pontšo oa PCB CCD

Ngola molaetsa wa hao mona mme o re romele wona